Bill Calfee

Gun Fool

Getting closer

CYA friends:

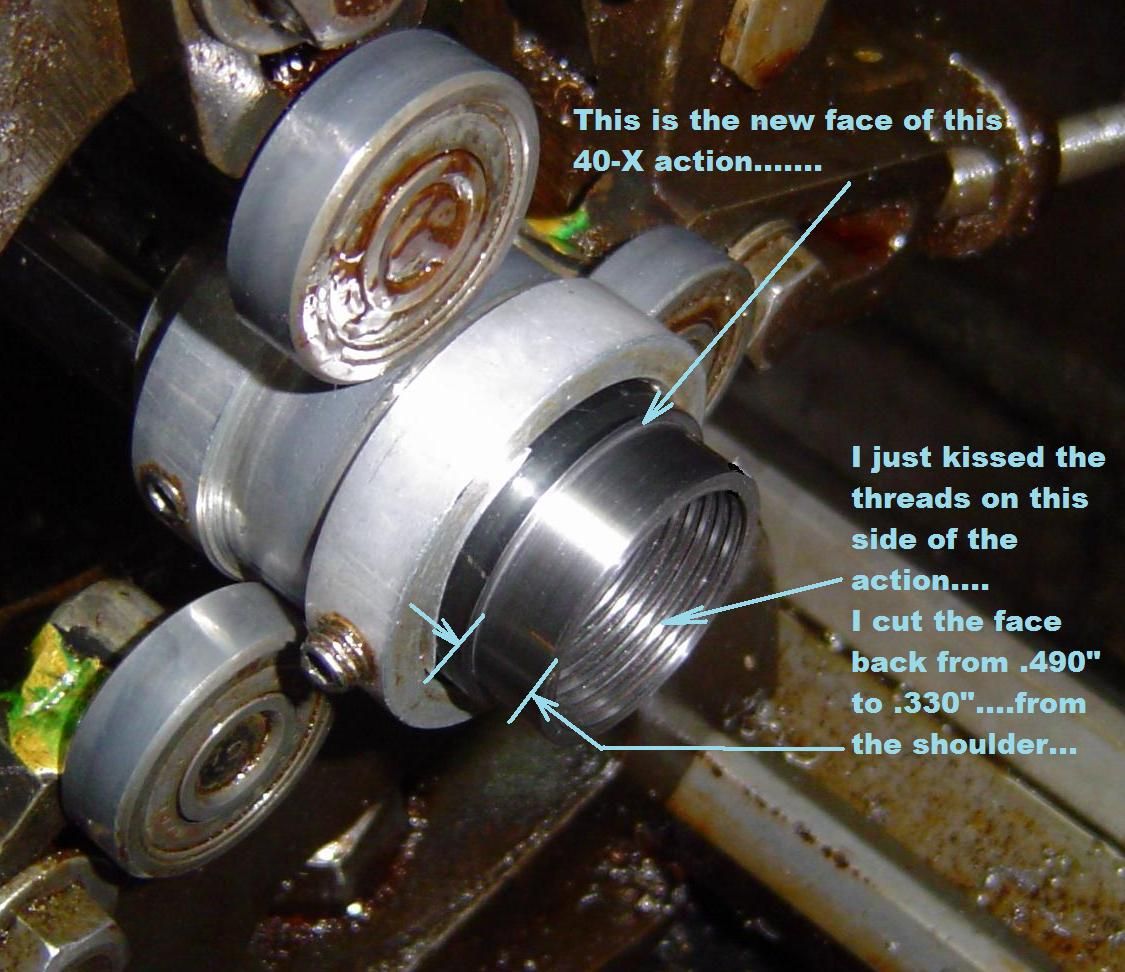

Today I trued up the crowns of the threads.........getting ready to re-cut them...

Plus, I cut the action back from .490" to the new action face/shoulder, to about .330"........I want to wind up at about .325" so I left enough for a clean-up cut after I chase the threads...

So far so good....actually, so far really good.....I've got my fingers crossed.

_______________________

Anyway, I have a comment and a question:

CYA is about learning, including me learning.

This 40-X was like all actions that are heat treated after they're machined, warped.

It took about .009" to completely clean up the crowns of the threads and center them on the breech bolt raceway.

Yes, .009".

I paid careful attention to what direction the warping took place.

In this action the high and low spots were directly in line from the loading port opening to the exact opposite side of it.

Now the question:

When this action was quenched after being brought to heat treat temp, obviously there is no metal in the loading port, and then full metal on the opposite side from it.

Which way did I find that it had warped?

In other words, did the action warp away from the loading port opening, or, did the metal on the opposite side of the loading port cause the action to warp toward the loading port side?

Anyone may answer who wishes to....

Anyway, if the world don't end I'll re-cut the threads tomorrow......and then the next operation will be to bore my new recoil lug.

Your friend, Bill Calfee

_______________________________

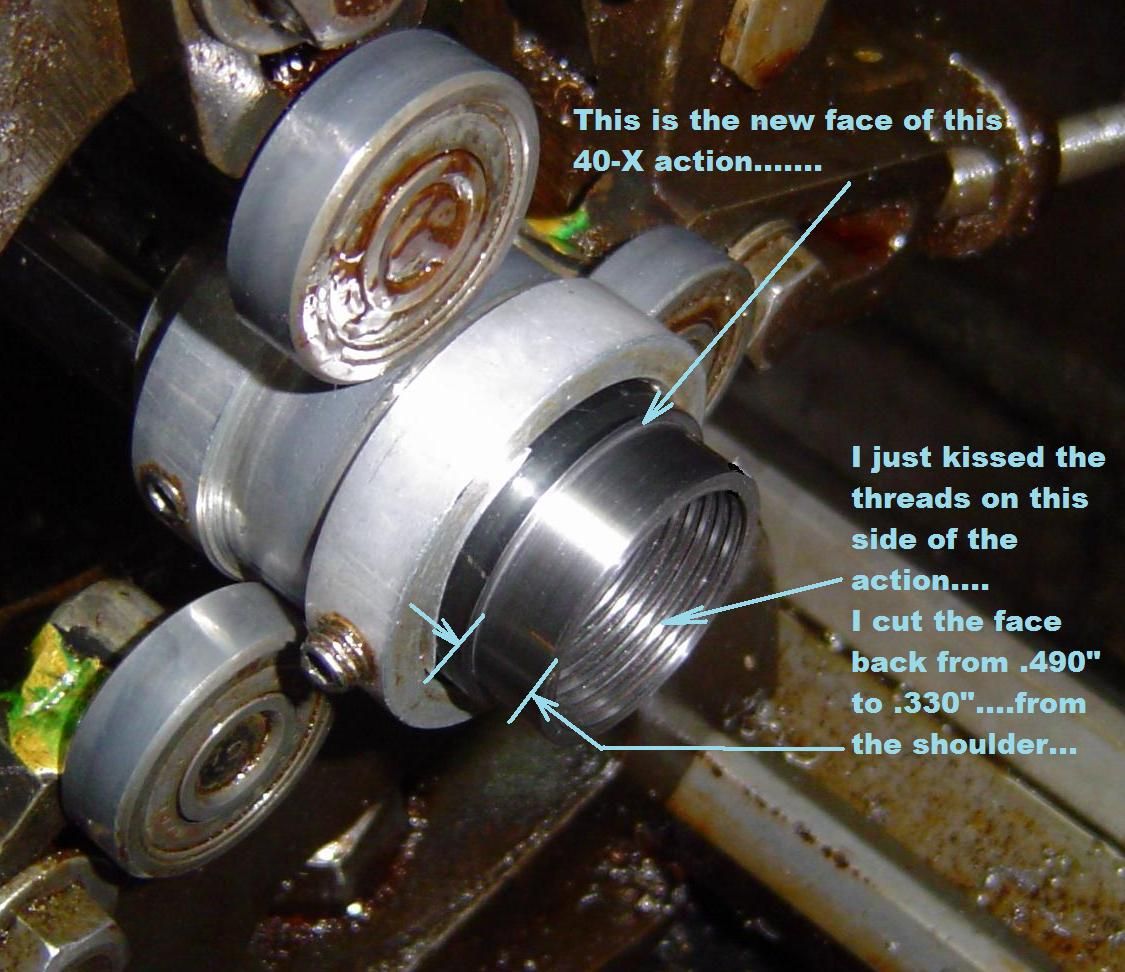

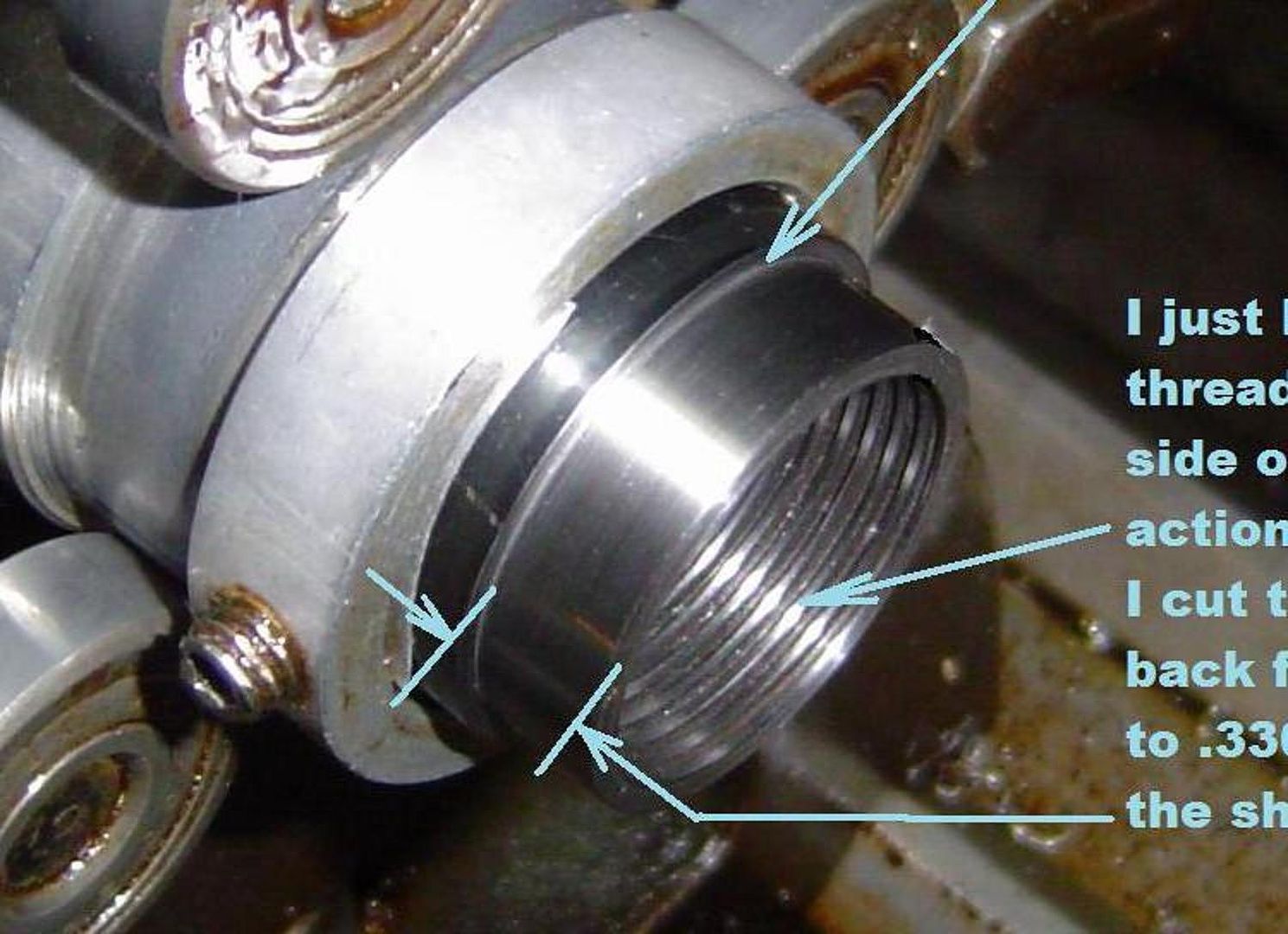

Here's a couple of pictures...

____________________________________

________________________________

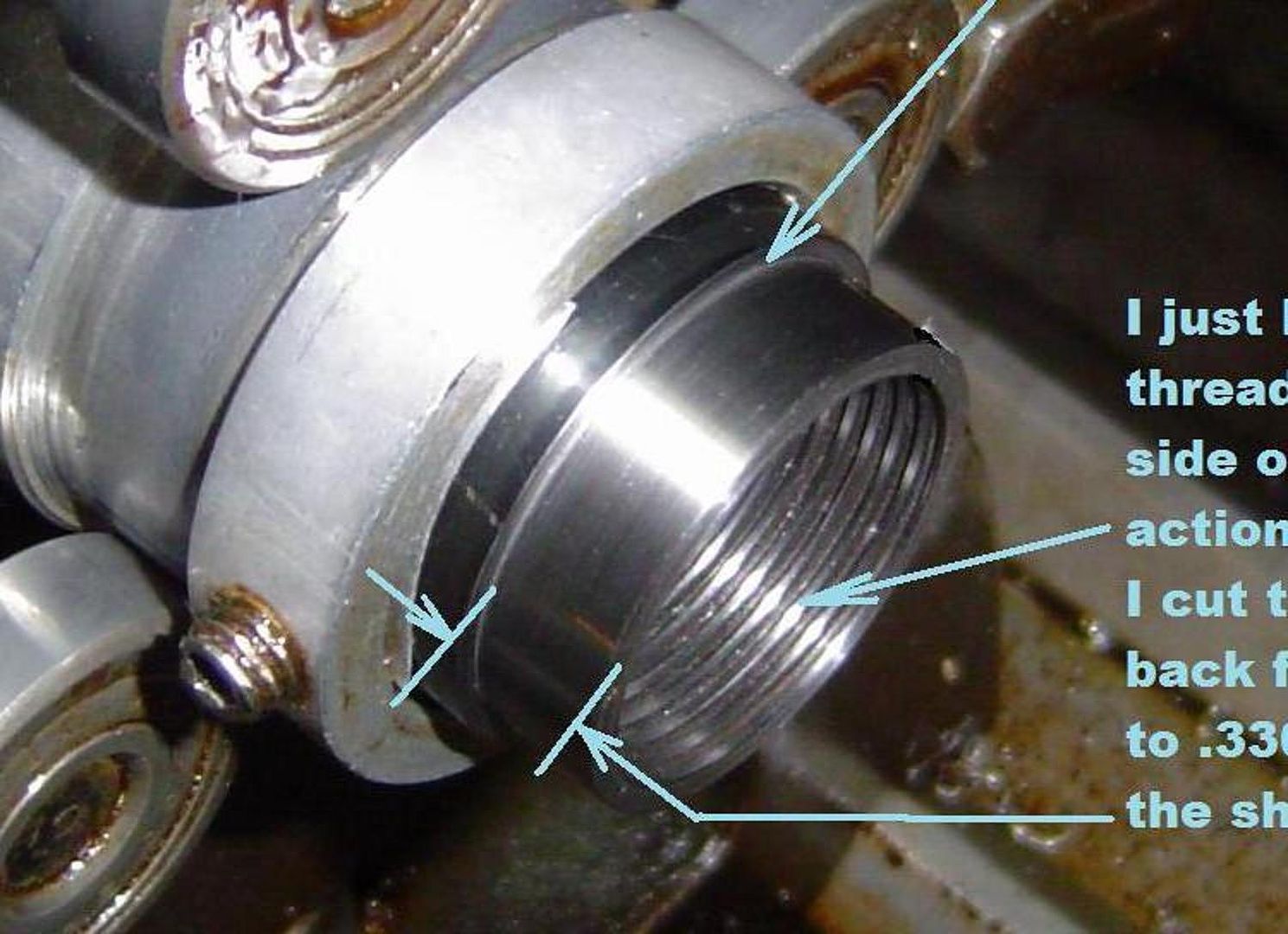

Here's a super closeup......

________________________________

CYA friends:

Today I trued up the crowns of the threads.........getting ready to re-cut them...

Plus, I cut the action back from .490" to the new action face/shoulder, to about .330"........I want to wind up at about .325" so I left enough for a clean-up cut after I chase the threads...

So far so good....actually, so far really good.....I've got my fingers crossed.

_______________________

Anyway, I have a comment and a question:

CYA is about learning, including me learning.

This 40-X was like all actions that are heat treated after they're machined, warped.

It took about .009" to completely clean up the crowns of the threads and center them on the breech bolt raceway.

Yes, .009".

I paid careful attention to what direction the warping took place.

In this action the high and low spots were directly in line from the loading port opening to the exact opposite side of it.

Now the question:

When this action was quenched after being brought to heat treat temp, obviously there is no metal in the loading port, and then full metal on the opposite side from it.

Which way did I find that it had warped?

In other words, did the action warp away from the loading port opening, or, did the metal on the opposite side of the loading port cause the action to warp toward the loading port side?

Anyone may answer who wishes to....

Anyway, if the world don't end I'll re-cut the threads tomorrow......and then the next operation will be to bore my new recoil lug.

Your friend, Bill Calfee

_______________________________

Here's a couple of pictures...

____________________________________

________________________________

Here's a super closeup......

________________________________