Bill Calfee

Gun Fool

Another piece of the puzzle.....

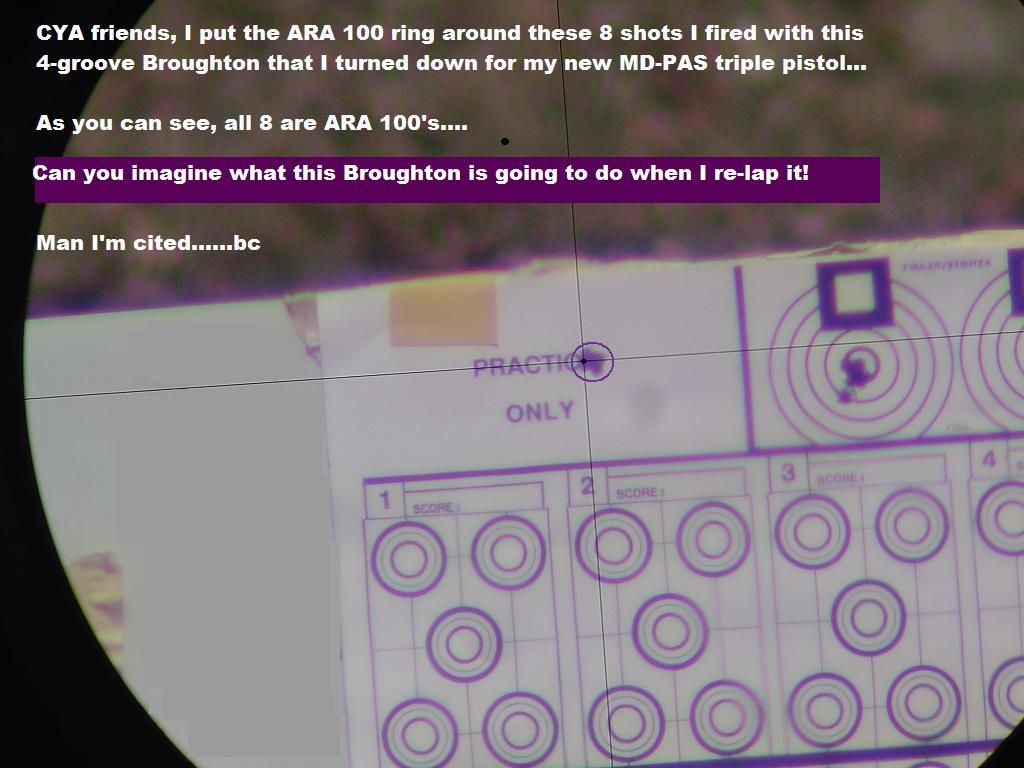

CYA friends:

Back about 2005 or 2006 I had Tim North, Broughton Barrels, build me two of his standard 4 groove barrels profiled for my XP pistols.

They had an enlarged breech end for about 5 inches, then stepped down to about .825" for the balance of the barrel.

A couple years later I decided to fit one of these to SPEC 4, Merlin....

And the one I fit on Merlin turned out to be killer, with Todd Wooten winning a PSL with it.

Anyway, I never fit the other barrel because it was very cooked.....

I don't believe I can determine how straight the bore of a barrel is, perfectly, but, I can point a barrel at the contrasting edge of something, like a white target against the green grass background and see the shadow line down the bore....

If I move my eye around and that shadow line seems to extend from breech to muzzle, I suspect the bore is fairly straight.

OK, here's why I'm telling you this:

This second 4 groove Broughton, that is really crooked on the outside, seemed like it had a fairly straight bore since a shadow line seems to extend from the muzzle to the breech when I look through it.

But it was too crooked for me to fool with, because if I turned it down to straighten it, the OD would probably go down into the .700" diameter range.

So it sat for years....

_______________________________

Some years back I decided to run a spearment with this crooked Broughton.....

I machined cooling fins into the enlarged breech end to see if that might help displace heat near the chamber and keep the viscosity of the wax more uniform throughout the entire bore...

I only shot it one time, never did cut extractor slots, and it shot so-so......

Course my machining the cooling fins distorted the bore, so I really needed to re-lap it, but never did....

So it laid around....

__________________________

Since I'm building myself a new MD-PAS triple pistol, and need a barrel, and remembering how killer the one on Merlin is, I decided to profile this barrel down, remove the cooling fins, and reduce it enough to straighten the outside......

I put a maximum reduction size limit of .775".......

In other words, if I could straighten it out without going less that .775" I'd try it on my new pistol....

CYA friends, I have to leave for an appointment.....

I'll finish this story later......

Your friend, Bill Calfee

_______________________

Here's the Broughton profiled with cooling fins......I never did cut extractor slots.......which is good as things have turned out.

CYA friends:

Back about 2005 or 2006 I had Tim North, Broughton Barrels, build me two of his standard 4 groove barrels profiled for my XP pistols.

They had an enlarged breech end for about 5 inches, then stepped down to about .825" for the balance of the barrel.

A couple years later I decided to fit one of these to SPEC 4, Merlin....

And the one I fit on Merlin turned out to be killer, with Todd Wooten winning a PSL with it.

Anyway, I never fit the other barrel because it was very cooked.....

I don't believe I can determine how straight the bore of a barrel is, perfectly, but, I can point a barrel at the contrasting edge of something, like a white target against the green grass background and see the shadow line down the bore....

If I move my eye around and that shadow line seems to extend from breech to muzzle, I suspect the bore is fairly straight.

OK, here's why I'm telling you this:

This second 4 groove Broughton, that is really crooked on the outside, seemed like it had a fairly straight bore since a shadow line seems to extend from the muzzle to the breech when I look through it.

But it was too crooked for me to fool with, because if I turned it down to straighten it, the OD would probably go down into the .700" diameter range.

So it sat for years....

_______________________________

Some years back I decided to run a spearment with this crooked Broughton.....

I machined cooling fins into the enlarged breech end to see if that might help displace heat near the chamber and keep the viscosity of the wax more uniform throughout the entire bore...

I only shot it one time, never did cut extractor slots, and it shot so-so......

Course my machining the cooling fins distorted the bore, so I really needed to re-lap it, but never did....

So it laid around....

__________________________

Since I'm building myself a new MD-PAS triple pistol, and need a barrel, and remembering how killer the one on Merlin is, I decided to profile this barrel down, remove the cooling fins, and reduce it enough to straighten the outside......

I put a maximum reduction size limit of .775".......

In other words, if I could straighten it out without going less that .775" I'd try it on my new pistol....

CYA friends, I have to leave for an appointment.....

I'll finish this story later......

Your friend, Bill Calfee

_______________________

Here's the Broughton profiled with cooling fins......I never did cut extractor slots.......which is good as things have turned out.

Last edited: