wsmallwood

Member

The post below is entitled “An Action’s Tale” as you can see. Obviously it will not be as involved “A Rifle’s Tale”, which I wrote some years ago because this is about evaluating an action; specifically the new Turbo V3 while the other was about a complete build. When I was thinking about this post I commented to a friend that I guess some people actually want to read this stuff. His comment was “He (Bill Calfee) is kind of a mystical figure. Only a few br shooters have met him in person nowadays”. I can hear the guffaws and “hmmps” right now over using the word mystical, but it’s appropriate. It in no way implies anything beyond human, but it does fit what most shooters, whether they realize it or not, think of Bill Calfee. Generally, people want to know what Bill’s opinion concerning rimfire accuracy so they can either deride it or utilize it. But for many, his writings might as well be generated by the Wizard of Oz hidden behind curtains, because they have no idea the personality of the man behind the words. Most wouldn’t know him if he showed up at a match. Thus “mystical” is the correct word.

I met Bill close to thirty years ago. But it was sometime after that before I had reason to visit his shop, which is small, unobtrusive building behind his house. Bill already had a reputation as a master gunsmith, and when I got there I recall seeing the well-worn path to the shop. My thought at that time was “Well build a better mousetrap I guess” and, at that time he had really built the better mousetrap. I also recall when I first went into the shop. I had heard the stories about a dirt floor and a lathe built over 70 years before, but like a lot of people I just thought it was part of the lore and not really true. It is true. There’s a dirt floor with some smattering of concrete but none where a person would walk or drop a delicate piece of equipment. If don’t think anyone would ever drive by Bill’s house and shop and think “there’s a place to get a great rifle built. I’m sure of it.” Yet many winners have come out of that shop built by a man obsessed with rimfire accuracy.

Bill doesn’t do a lot of work for customers now so the path is not so well worn, and the driveway simply looks like part of the yard. It kind of reminds me of an old Eagles song of which the title escapes me right now but part of the lyrics were something like “bugs on the windows and dust on the floor.” Life moves on relentlessly for all of us. But Bill still has a passion and still seems as sharp and obsessed with his goals as ever, and what comes out of his mailbox provides the evidence that the work is there if he wanted it.

Bill Calfee is exactly what Mike Ross says: “A Remarkably meticulous man, who simply loves what he does, perhaps to the exclusion of nearly everything else”. I’ve heard if you do what you love you’ll never work a day in your life. So, maybe Bill has achieved nirvana or something similar without even realizing it. Bill is personable, generous, and patient with those he knows but careful about who he allows into his world. While I’m not going to get into a biography, he is also one of the best shooters and wind readers I’ve ever seen. He was a regular BR-50 shooter back in the day and was always competitive. To add to that he was competitive with an XP pistol. The only times I ever saw him shoot a rifle in match would be if he was trying a customer’s rifle. For those who have criticized him as a non-shooter they could never be more wrong. It’s true that he’s really not able to travel and shoot these days and I imagine a five card match even at Wood’s Township range, about seven miles from his home, would stretch the limits of his endurance. It’s one of those “if you only knew him when” type things

But enough of that the name of the following story is:

AN ACTION’S TALE

I guess this is a good time to stress that this post is not about PAS and SAP or about any other product or even any other V-3. It is simply about the one that I received and the evaluation of the same.

I’m generally not a first adopter, and quite frankly there was no reason for me to want a new rifle so I was somewhat indecisive as to whether or not to acquire a V-3. But it seemed like a good collaboration between Bill Calfee, Anthony DiOrio, and Tom Wilkinson so the pedigree was there. I will say that I did not purchase the action because it was PAS or that I automatically assumed it would be produce something better than any other rifle I currently own. But like a lot of you, I’m a firearms aficionado and this was simply the next step. So I chose to early adopt and ordered one shortly after the first batch. I assume mine was from the second batch.

I contacted Anthony DiOrio to order the action around late December or early January. While I realize I was buying something that he was selling. I found him very personable and helpful and he has continued to be exactly that. I even messaged him a couple of times during the waiting period concerning some measurements and other things and found him nothing but fast to help. So, my personal opinion is that he has a typical shooter’s personality. He’s willing to help and wants his product to be the best. Not just to sell, but also as a source of pride.

After a few weeks wait I received the V-3 action. It is a beautiful piece of work. It comes with nice dovetail scope mounts and mine came with an additional longer bolt knob as Bill had mentioned would be useful. Of course that’s cosmetics, and I was more interested in mechanics. I looked it over and the first thing I checked was lug contact. To be honest, I was initially somewhat skeptical, which is normal for me, but it had no trigger so I withheld judgment. As soon as I got home from work that day, I put a trigger in it. It comes with a slotted trigger hanger, something we will get into a little later. Using what I had which was highlighter then grease, I could tell contact looked better than I initially thought but could not make a determination for sure and proper lug contact is critical. Well, if I couldn’t tell for sure I knew someone who could, so I contacted Bill Calfee to see if he would evaluate the action particularly the lug contact. Bill agreed and we set a time. Unfortunately the weather turned cold, and Bill did not want to work in the cold. I really don’t blame him. My schedule was so hectic that it was May 9 2019, almost a month later that I decided to again contact Bill. Oddly enough he contacted me first on that same day. So, we decided that Saturday May 11, 2019 would be a good day. I would like to mention that Foster Arvin had recently acquired a Calfee XP built in the early ‘90’s and Bill was hoping Foster would accompany me and bring his pistol. I called Foster and he agreed so about 9 A.M. that Saturday we headed northwest to Borden, IN.

We arrived at Bill’s at about 12:30 P.M., and he met us at the shop door. He initially ignored my V-3 and promptly took possession of Foster’s pistol, which he proceeded to disassemble and check carefully. He remarked that it was a Grade II and named the person he built it for, noted that everything was in line and that it did not appear to have been shot much or messed with and looked good. He finally chambered a round and then extracted it and noted that the lands and grooves were sharp which further indicated low usage. He measured the spread of the stock when under slight pressure and noted that it was within tolerances. While he had agreed to evaluate my action I believe there was no doubt he was enamored with the pistol. Bill loves those pistols and every one of them is special to him. He was very glad to see this one and to see the shape it was in. He did note that it was built over 25 years ago and probably needed upgrades, which is why he wants to see the Turbo pistol a reality. I can understand why he wants that, but if a person has an original Calfee pistol they’re probably not going to have it modified much unless Bill does the work.

Now, while the description of the pistol evaluation took one paragraph the evaluation of the pistol took about an hour. So now it was the V-3’s turn.

THE V-3 EVALUATION

Bill turns to me and simply holds his hand out for the V-3 and I simply hand it to him. I have noted numerous times before I am neither a machinist or a gunsmith. I understand most of what I see after I see it, but that does not mean that I would or could think of the proper way to do it. Bill has a chair in his shop that has been there since as long as I can recall. I don’t want to be in the way, and I trust his judgement so I simply sit down. That’s my usual position while Bill is working. He somewhat chastises me for not having pencil and paper to take notes. I assure him I have a good memory. I only hope that I do it justice.

Bill works the action a few times just feeling for any abnormality then quickly removes the bolt and disassembles it. The first thing he mentions is the spring, which he thinks is a Pepper spring or a clone of a Pepper spring, would give the pin about a 20lb preload. Quite enough to drive the .040” wide firing pin as was quickly demonstrated. He also notes that I have replaced the slotted trigger hanger with another and asks why. I told him that I had a problem with the pins and with one in particular. Actually, I bent it. He noted that there was some issue with that but it’s an easy fix. Also, as you will see the slotted hanger can be important.

Bill reassembles the bolt and measures the firing pin fall and notes that it is .187” as the trigger is installed. He also measures the distance to the mechanical stop and notes that is .014”. All is good with that part. So far, so good. (Measuring firing pin fall is pretty self-explanatory. I can measure the mechanical stop distance but may not describe it well. Bill may want to address that.)

Bill again disassembles the bolt and installs what looks like a barrel stub with a small bolt in it in the front of the action. Actually at this point I’m not paying a lot of attention; just kind of casually observing. Bill tells me I need to watch the process, so I get up and watch what he’s doing. He inserts the bolt body into the action and I realize that the “barrel stub” is a tool designed to create a spring load in order to simulate the cocking of the rifle with both a trigger and a barrel installed, and I assume to also simulate that it is loaded.

Bill then carefully puts a film of grease on each of the lugs then inserts those over the bolt body and works the action. He then removes the lugs and after careful inspection he wipes the grease and repeats the process. He looks at me and says “So, you were worried about the lug contact, you have no reason to worry, these are perfect.” He shows me the lugs and the swipes made on the grease by the lug motion of the cocking motion. They appear perfect. On the right hand side of the lug raceway there is small relief cut it is perfectly outlined. I have the proof I needed, the lugs are good.

Bill proceeds to check every aspect of the action, examining the closing cam, noting refinements that have been incorporated since the initial prototype actions. After his inspection he states something I thought I would never hear. He says “This action is ready for a barrel, it needs no blueprinting”. I’m thinking “But, but Bill don’t all to them need it”? I suppose the blueprinting is incorporated into the work so there’s nothing else to do but install the barrel and put it in a stock.

But Bill, always the thinker, says once again “Blueprinting is one thing, it doesn’t need any, but refinements are another, and they’re a matter of personal taste but there are some things you can do” Aha, here’s the Bill I really know. You can make it better, stronger, faster, eh you get the picture. So what can be done? The action is ready for a barrel. It’s almost ready to shoot. This is where it gets somewhat interesting.

Bill shows me his V-3. It doesn’t have a barrel but it’s in a stock. I’ll have to say it has a really nice bolt knob and I wish I could have one like it, but it’s a one off Calfee. So after cocking it a few times with the almost passive but somehow dramatic flair I’ve come to expect from Bill he hands it to me and tells me to cock it, and I did. Whoa, this is a three lug; they’re just naturally a little harder to cock and should be. Not this one. I doubt that most two lugs cock easier. Super easy and super smooth.

Bill has reassembled my action but once again takes it apart looks at something, then reassembles and measures the firing pin fall again at .187” and the distance to the mechanical stop after firing at .014”. He then says that his firing pin fall is .214” and this is where the slotted trigger hanger is crucial. He tells me I can use the slotted trigger hanger to get more firing pin fall but will have to carefully measure to keep the mechanical stop at no less than .010”. By doing this Bill believes I can use a spring with an 8 lb. preload and still drive the firing pin while achieving the super smooth and super easy cocking motion. While he has narrowed his pin to .033” I believe, he does not feel that is necessary to achieve proper ignition. With the current spring and firing pin fall the ignition is great which is evident by the indentation made. But it would be great to get that type ignition with that type of cocking. And, as Bill says, all this is easier on the parts. So, it seems a win win. I will say the action is already pretty smooth as It sits.

I also need to note my problems with the original trigger hanger. I contacted Anthony DiOrio and he explained that one side of the pin is a pressed fit and the other is not. That made perfect sense because I removed the pin and with no real reason reinstalled one from one side and one from the other. Needless to say the pressed fit works.

The other aid suggested for easy cocking is the bolt knob. As I said mine came with a longer one and I also purchased one. One like Bill’s would be great but there we go again. I’m not a machinist. But the longer knob obviously provides greater leverage.

So to summarize, while I was not suspect of the V-3’s craftsmanship I did need verification and most actions I have seen need a little lug work. Having someone with the patience, tools, and experience to check all that is invaluable because regardless of what you have, if you don’t have complete trust in it, you will never be able to do well with it.

Bill also evaluated a barrel for me while I was there and describing that process could take another page but it is interesting. He says it’s the best barrel I ever brought into his shop which, as Foster said, is going some considering the barrel that was on Gingersnap. Hopefully, it will all come together perfectly and I have every confidence in the gunsmith putting it together.

As for Bill what can we say? He no longer builds guns except for his own enjoyment, but when he works he is as meticulous as ever. He has patience that is almost inhuman but everything must be inspected and must pass muster. Nothing can be left to chance. This quick little story summarizes about three hours of evaluation. Bill can fill in more detail if he wishes because I know there are things he noticed but did not mention.

Hopefully Bill will be around for a long time. It’s a three hour drive for me but to have a good gunsmith that close is nice. Like my friend who called him mystical said “there’s not a Bill Calfee on every street corner”.

I met Bill close to thirty years ago. But it was sometime after that before I had reason to visit his shop, which is small, unobtrusive building behind his house. Bill already had a reputation as a master gunsmith, and when I got there I recall seeing the well-worn path to the shop. My thought at that time was “Well build a better mousetrap I guess” and, at that time he had really built the better mousetrap. I also recall when I first went into the shop. I had heard the stories about a dirt floor and a lathe built over 70 years before, but like a lot of people I just thought it was part of the lore and not really true. It is true. There’s a dirt floor with some smattering of concrete but none where a person would walk or drop a delicate piece of equipment. If don’t think anyone would ever drive by Bill’s house and shop and think “there’s a place to get a great rifle built. I’m sure of it.” Yet many winners have come out of that shop built by a man obsessed with rimfire accuracy.

Bill doesn’t do a lot of work for customers now so the path is not so well worn, and the driveway simply looks like part of the yard. It kind of reminds me of an old Eagles song of which the title escapes me right now but part of the lyrics were something like “bugs on the windows and dust on the floor.” Life moves on relentlessly for all of us. But Bill still has a passion and still seems as sharp and obsessed with his goals as ever, and what comes out of his mailbox provides the evidence that the work is there if he wanted it.

Bill Calfee is exactly what Mike Ross says: “A Remarkably meticulous man, who simply loves what he does, perhaps to the exclusion of nearly everything else”. I’ve heard if you do what you love you’ll never work a day in your life. So, maybe Bill has achieved nirvana or something similar without even realizing it. Bill is personable, generous, and patient with those he knows but careful about who he allows into his world. While I’m not going to get into a biography, he is also one of the best shooters and wind readers I’ve ever seen. He was a regular BR-50 shooter back in the day and was always competitive. To add to that he was competitive with an XP pistol. The only times I ever saw him shoot a rifle in match would be if he was trying a customer’s rifle. For those who have criticized him as a non-shooter they could never be more wrong. It’s true that he’s really not able to travel and shoot these days and I imagine a five card match even at Wood’s Township range, about seven miles from his home, would stretch the limits of his endurance. It’s one of those “if you only knew him when” type things

But enough of that the name of the following story is:

AN ACTION’S TALE

I guess this is a good time to stress that this post is not about PAS and SAP or about any other product or even any other V-3. It is simply about the one that I received and the evaluation of the same.

I’m generally not a first adopter, and quite frankly there was no reason for me to want a new rifle so I was somewhat indecisive as to whether or not to acquire a V-3. But it seemed like a good collaboration between Bill Calfee, Anthony DiOrio, and Tom Wilkinson so the pedigree was there. I will say that I did not purchase the action because it was PAS or that I automatically assumed it would be produce something better than any other rifle I currently own. But like a lot of you, I’m a firearms aficionado and this was simply the next step. So I chose to early adopt and ordered one shortly after the first batch. I assume mine was from the second batch.

I contacted Anthony DiOrio to order the action around late December or early January. While I realize I was buying something that he was selling. I found him very personable and helpful and he has continued to be exactly that. I even messaged him a couple of times during the waiting period concerning some measurements and other things and found him nothing but fast to help. So, my personal opinion is that he has a typical shooter’s personality. He’s willing to help and wants his product to be the best. Not just to sell, but also as a source of pride.

After a few weeks wait I received the V-3 action. It is a beautiful piece of work. It comes with nice dovetail scope mounts and mine came with an additional longer bolt knob as Bill had mentioned would be useful. Of course that’s cosmetics, and I was more interested in mechanics. I looked it over and the first thing I checked was lug contact. To be honest, I was initially somewhat skeptical, which is normal for me, but it had no trigger so I withheld judgment. As soon as I got home from work that day, I put a trigger in it. It comes with a slotted trigger hanger, something we will get into a little later. Using what I had which was highlighter then grease, I could tell contact looked better than I initially thought but could not make a determination for sure and proper lug contact is critical. Well, if I couldn’t tell for sure I knew someone who could, so I contacted Bill Calfee to see if he would evaluate the action particularly the lug contact. Bill agreed and we set a time. Unfortunately the weather turned cold, and Bill did not want to work in the cold. I really don’t blame him. My schedule was so hectic that it was May 9 2019, almost a month later that I decided to again contact Bill. Oddly enough he contacted me first on that same day. So, we decided that Saturday May 11, 2019 would be a good day. I would like to mention that Foster Arvin had recently acquired a Calfee XP built in the early ‘90’s and Bill was hoping Foster would accompany me and bring his pistol. I called Foster and he agreed so about 9 A.M. that Saturday we headed northwest to Borden, IN.

We arrived at Bill’s at about 12:30 P.M., and he met us at the shop door. He initially ignored my V-3 and promptly took possession of Foster’s pistol, which he proceeded to disassemble and check carefully. He remarked that it was a Grade II and named the person he built it for, noted that everything was in line and that it did not appear to have been shot much or messed with and looked good. He finally chambered a round and then extracted it and noted that the lands and grooves were sharp which further indicated low usage. He measured the spread of the stock when under slight pressure and noted that it was within tolerances. While he had agreed to evaluate my action I believe there was no doubt he was enamored with the pistol. Bill loves those pistols and every one of them is special to him. He was very glad to see this one and to see the shape it was in. He did note that it was built over 25 years ago and probably needed upgrades, which is why he wants to see the Turbo pistol a reality. I can understand why he wants that, but if a person has an original Calfee pistol they’re probably not going to have it modified much unless Bill does the work.

Now, while the description of the pistol evaluation took one paragraph the evaluation of the pistol took about an hour. So now it was the V-3’s turn.

THE V-3 EVALUATION

Bill turns to me and simply holds his hand out for the V-3 and I simply hand it to him. I have noted numerous times before I am neither a machinist or a gunsmith. I understand most of what I see after I see it, but that does not mean that I would or could think of the proper way to do it. Bill has a chair in his shop that has been there since as long as I can recall. I don’t want to be in the way, and I trust his judgement so I simply sit down. That’s my usual position while Bill is working. He somewhat chastises me for not having pencil and paper to take notes. I assure him I have a good memory. I only hope that I do it justice.

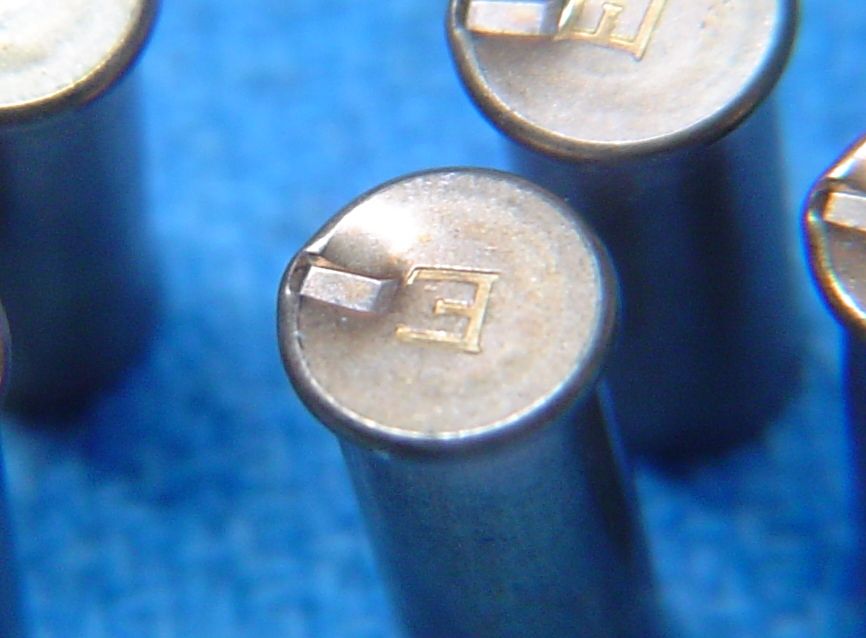

Bill works the action a few times just feeling for any abnormality then quickly removes the bolt and disassembles it. The first thing he mentions is the spring, which he thinks is a Pepper spring or a clone of a Pepper spring, would give the pin about a 20lb preload. Quite enough to drive the .040” wide firing pin as was quickly demonstrated. He also notes that I have replaced the slotted trigger hanger with another and asks why. I told him that I had a problem with the pins and with one in particular. Actually, I bent it. He noted that there was some issue with that but it’s an easy fix. Also, as you will see the slotted hanger can be important.

Bill reassembles the bolt and measures the firing pin fall and notes that it is .187” as the trigger is installed. He also measures the distance to the mechanical stop and notes that is .014”. All is good with that part. So far, so good. (Measuring firing pin fall is pretty self-explanatory. I can measure the mechanical stop distance but may not describe it well. Bill may want to address that.)

Bill again disassembles the bolt and installs what looks like a barrel stub with a small bolt in it in the front of the action. Actually at this point I’m not paying a lot of attention; just kind of casually observing. Bill tells me I need to watch the process, so I get up and watch what he’s doing. He inserts the bolt body into the action and I realize that the “barrel stub” is a tool designed to create a spring load in order to simulate the cocking of the rifle with both a trigger and a barrel installed, and I assume to also simulate that it is loaded.

Bill then carefully puts a film of grease on each of the lugs then inserts those over the bolt body and works the action. He then removes the lugs and after careful inspection he wipes the grease and repeats the process. He looks at me and says “So, you were worried about the lug contact, you have no reason to worry, these are perfect.” He shows me the lugs and the swipes made on the grease by the lug motion of the cocking motion. They appear perfect. On the right hand side of the lug raceway there is small relief cut it is perfectly outlined. I have the proof I needed, the lugs are good.

Bill proceeds to check every aspect of the action, examining the closing cam, noting refinements that have been incorporated since the initial prototype actions. After his inspection he states something I thought I would never hear. He says “This action is ready for a barrel, it needs no blueprinting”. I’m thinking “But, but Bill don’t all to them need it”? I suppose the blueprinting is incorporated into the work so there’s nothing else to do but install the barrel and put it in a stock.

But Bill, always the thinker, says once again “Blueprinting is one thing, it doesn’t need any, but refinements are another, and they’re a matter of personal taste but there are some things you can do” Aha, here’s the Bill I really know. You can make it better, stronger, faster, eh you get the picture. So what can be done? The action is ready for a barrel. It’s almost ready to shoot. This is where it gets somewhat interesting.

Bill shows me his V-3. It doesn’t have a barrel but it’s in a stock. I’ll have to say it has a really nice bolt knob and I wish I could have one like it, but it’s a one off Calfee. So after cocking it a few times with the almost passive but somehow dramatic flair I’ve come to expect from Bill he hands it to me and tells me to cock it, and I did. Whoa, this is a three lug; they’re just naturally a little harder to cock and should be. Not this one. I doubt that most two lugs cock easier. Super easy and super smooth.

Bill has reassembled my action but once again takes it apart looks at something, then reassembles and measures the firing pin fall again at .187” and the distance to the mechanical stop after firing at .014”. He then says that his firing pin fall is .214” and this is where the slotted trigger hanger is crucial. He tells me I can use the slotted trigger hanger to get more firing pin fall but will have to carefully measure to keep the mechanical stop at no less than .010”. By doing this Bill believes I can use a spring with an 8 lb. preload and still drive the firing pin while achieving the super smooth and super easy cocking motion. While he has narrowed his pin to .033” I believe, he does not feel that is necessary to achieve proper ignition. With the current spring and firing pin fall the ignition is great which is evident by the indentation made. But it would be great to get that type ignition with that type of cocking. And, as Bill says, all this is easier on the parts. So, it seems a win win. I will say the action is already pretty smooth as It sits.

I also need to note my problems with the original trigger hanger. I contacted Anthony DiOrio and he explained that one side of the pin is a pressed fit and the other is not. That made perfect sense because I removed the pin and with no real reason reinstalled one from one side and one from the other. Needless to say the pressed fit works.

The other aid suggested for easy cocking is the bolt knob. As I said mine came with a longer one and I also purchased one. One like Bill’s would be great but there we go again. I’m not a machinist. But the longer knob obviously provides greater leverage.

So to summarize, while I was not suspect of the V-3’s craftsmanship I did need verification and most actions I have seen need a little lug work. Having someone with the patience, tools, and experience to check all that is invaluable because regardless of what you have, if you don’t have complete trust in it, you will never be able to do well with it.

Bill also evaluated a barrel for me while I was there and describing that process could take another page but it is interesting. He says it’s the best barrel I ever brought into his shop which, as Foster said, is going some considering the barrel that was on Gingersnap. Hopefully, it will all come together perfectly and I have every confidence in the gunsmith putting it together.

As for Bill what can we say? He no longer builds guns except for his own enjoyment, but when he works he is as meticulous as ever. He has patience that is almost inhuman but everything must be inspected and must pass muster. Nothing can be left to chance. This quick little story summarizes about three hours of evaluation. Bill can fill in more detail if he wishes because I know there are things he noticed but did not mention.

Hopefully Bill will be around for a long time. It’s a three hour drive for me but to have a good gunsmith that close is nice. Like my friend who called him mystical said “there’s not a Bill Calfee on every street corner”.