Bill Calfee

Gun Fool

The rest of the story.........

CYA friends:

There's absolutely no reason to use a rear entry action wrench when removing and installing the barrel of a valuable RFBR gun....

With one exception:

That being if you shoot a glue in........

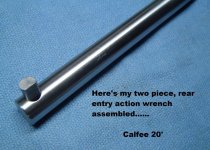

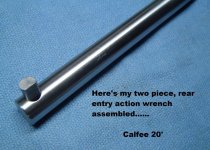

And then, the only "safe" rear entry action wrench must be similar to this one I made 20 some odd years ago, so I could deal with glue-ins.

Otherwise, this is the safest and most foolproof action wrench everyone should use to remove and install the barrel on your valuable RFBR gun, and it fits all rear lockup RFBR actions.

Now.................................

The rest of the story:

No rear entry action wrench, including the one I use, gives you the "feel" necessary when torquing the barrel of your RFBR gun, like the crescent wrench does...

CYA friends:

How much torque should be put on the .750" diameter barrel threads, that we use in big time RFBR today, when installing a barrel?

Does anyone know?

Your friend, Bill gun fool Calfee.

_______________________________

PS:

CYA friends:

The question I asked above is not a "trick" question.....

But it is a very complicated question.......

The correct answer is one of the reasons why rear entry action wrenches are worthless for properly removing and installing the barrels on valuable RFBR guns.....

CYA friends:

There's absolutely no reason to use a rear entry action wrench when removing and installing the barrel of a valuable RFBR gun....

With one exception:

That being if you shoot a glue in........

And then, the only "safe" rear entry action wrench must be similar to this one I made 20 some odd years ago, so I could deal with glue-ins.

Otherwise, this is the safest and most foolproof action wrench everyone should use to remove and install the barrel on your valuable RFBR gun, and it fits all rear lockup RFBR actions.

Now.................................

The rest of the story:

No rear entry action wrench, including the one I use, gives you the "feel" necessary when torquing the barrel of your RFBR gun, like the crescent wrench does...

CYA friends:

How much torque should be put on the .750" diameter barrel threads, that we use in big time RFBR today, when installing a barrel?

Does anyone know?

Your friend, Bill gun fool Calfee.

_______________________________

PS:

CYA friends:

The question I asked above is not a "trick" question.....

But it is a very complicated question.......

The correct answer is one of the reasons why rear entry action wrenches are worthless for properly removing and installing the barrels on valuable RFBR guns.....

Last edited: