Bill Calfee

Gun Fool

Is anything applicable to the DiOrio V-3?

CYA accuracy fool friends:

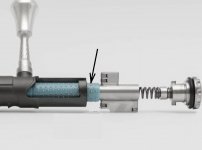

Is there anything on this PAS ignition centerfire breech bolt that would be applicable to the DiOrio V-3, as an improvement?

The only thing I see that would be an improvement, is the roller bearing on the 6 o'clock cocking piece teat...

This would be a functional improvement only, not an accuracy enhancement improvement.

The 12 o'clock cocking teat, and rollers, is not needed on the V-3.

In my opinion:

I can see the "seemingly valid logic" for having both 12 and 6 o'clock cocking teats, rollers or not, because of the blue material sandwiched between the OD of the firing pin and ID of the breech bolt.....

I used the term "seemingly valid logic" above for this reason:

The 12 o'clock area of the firing pin, just in front of the firing pin head, is a bearing surface during cocking.

This 12 o'clock surface is a bearing surface whether there's twin cocking piece teats, or, the single teat at 6 o'clock, like in the late V-1 and V-3 DiOrio Turbo actions...

(This is one reason Anthony DiOrio deleted the 12 o'clock cocking teat and ramp from his late V-1 and V-3's.

Which is an improvement...)

This 12 o'clock bearing surface is caused by the upward pressure of the transfer bar, of the trigger, pushing up on the bottom of the cocking piece, which is due to the angled engagement surfaces of the Remington pattern trigger.

This upward pressure is present in all actions that use the Remington pattern trigger....

Including the PAS ignition centerfire bolt in the above picture....

In other words, the 12 o'clock portion of the blue material of this breech bolt's firing pin, is still a bearing surface.

This is why I used the term "seemingly valid logic" in my statement above...

I really see no other features of this PAS ignition centerfire breech bolt that would be an accuracy enhancement to the DiOrio V-1 or V-3..

Your pistol fool friend, BC

____________________

PS:

"But Calfee, maybe the blue material would be more friction free than the metal to metal contact of the DiOrio V-1 and V-3?"

I would have to see demonstrations before I could decide if there's a benefit in this area, or not.

In other words, I'd have to run my 10 round case head penetration test on both, then see if a greater percentage of 10-0 runs were produced by the blue material, or, simple metal to metal contact.

CYA accuracy fool friends:

Is there anything on this PAS ignition centerfire breech bolt that would be applicable to the DiOrio V-3, as an improvement?

The only thing I see that would be an improvement, is the roller bearing on the 6 o'clock cocking piece teat...

This would be a functional improvement only, not an accuracy enhancement improvement.

The 12 o'clock cocking teat, and rollers, is not needed on the V-3.

In my opinion:

I can see the "seemingly valid logic" for having both 12 and 6 o'clock cocking teats, rollers or not, because of the blue material sandwiched between the OD of the firing pin and ID of the breech bolt.....

I used the term "seemingly valid logic" above for this reason:

The 12 o'clock area of the firing pin, just in front of the firing pin head, is a bearing surface during cocking.

This 12 o'clock surface is a bearing surface whether there's twin cocking piece teats, or, the single teat at 6 o'clock, like in the late V-1 and V-3 DiOrio Turbo actions...

(This is one reason Anthony DiOrio deleted the 12 o'clock cocking teat and ramp from his late V-1 and V-3's.

Which is an improvement...)

This 12 o'clock bearing surface is caused by the upward pressure of the transfer bar, of the trigger, pushing up on the bottom of the cocking piece, which is due to the angled engagement surfaces of the Remington pattern trigger.

This upward pressure is present in all actions that use the Remington pattern trigger....

Including the PAS ignition centerfire bolt in the above picture....

In other words, the 12 o'clock portion of the blue material of this breech bolt's firing pin, is still a bearing surface.

This is why I used the term "seemingly valid logic" in my statement above...

I really see no other features of this PAS ignition centerfire breech bolt that would be an accuracy enhancement to the DiOrio V-1 or V-3..

Your pistol fool friend, BC

____________________

PS:

"But Calfee, maybe the blue material would be more friction free than the metal to metal contact of the DiOrio V-1 and V-3?"

I would have to see demonstrations before I could decide if there's a benefit in this area, or not.

In other words, I'd have to run my 10 round case head penetration test on both, then see if a greater percentage of 10-0 runs were produced by the blue material, or, simple metal to metal contact.