Bill Calfee

Gun Fool

Hall ignition upgrade...

This is for our SAP ignition friends...

Maybe this will inspire anyone with a Hall RFBR rifle sitting in their closet to think about getting it back into competition.

_________________________

In my opinion...........

If you have a Hall and would like to upgrade the ignition, I would highly advise you to have a schmidt who thoroughly understands rimfire ignition do the upgrade.....OK.

I'm not saying a Hall owner couldn't do it themself........

Properly done, this upgrade will add momentum, and uniformity, to the Hall spring dependent ignition...

_____________________________

First......here's some pictures to study.....then later I'll describe how everything is put together...and modified..

Picture one...

________________________________

________________________________

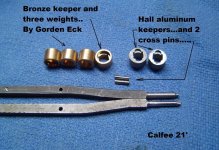

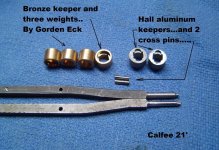

The picture above shows an early and late Hall firing pin, two Hall aluminum keepers, and cross pins, and three bronze weights and a bronze keeper that Gordon Eck made for me years ago....

In case I forget to mention it later, the cross pin has to be shortened a few thousandths when using the Eck keeper.....I'm telling you this now while it just crossed my mind...in case I forget to mention it later..

_________________

This next picture shows a closeup of the early and late pins........notice there's more meat behind the pin tip of the early pin.....to be able to easily enlarge the footprint....

The late pin is more difficult to enlarge the footprint without moving the entire firing pin forward......

Although, if I had the late pin I'd do whatever it took......this probably really requires the services of a schmidt well versed in rimfire ignition...

_____________________________________

________________________________

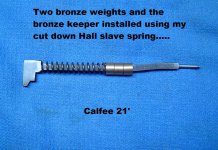

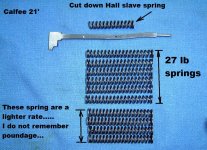

This last picture is where it all comes together, which I'll explain later on....

___________________________________

Your pistol fool friend, Bill Calfee

PS:

Bronze and steel are close to the same weight, which is of course much heavier than aluminum..

But man, if one could get carbide weights......one could wake up the Hall spring dependent ignition even more......

______________________

I need a favor of you CYA folks....

If you have comments about any of this, please withhold them until I get through this thing because it's fairly complicated and needs to be condensed as much as possible......OK.

_____________________

PS #2:

I finally located the picture of an early Hall footprint, right, and the footprint after my modification...left.

An amazing difference.....

This picture was taken in November of 2003.....

This is for our SAP ignition friends...

Maybe this will inspire anyone with a Hall RFBR rifle sitting in their closet to think about getting it back into competition.

_________________________

In my opinion...........

If you have a Hall and would like to upgrade the ignition, I would highly advise you to have a schmidt who thoroughly understands rimfire ignition do the upgrade.....OK.

I'm not saying a Hall owner couldn't do it themself........

Properly done, this upgrade will add momentum, and uniformity, to the Hall spring dependent ignition...

_____________________________

First......here's some pictures to study.....then later I'll describe how everything is put together...and modified..

Picture one...

________________________________

________________________________

The picture above shows an early and late Hall firing pin, two Hall aluminum keepers, and cross pins, and three bronze weights and a bronze keeper that Gordon Eck made for me years ago....

In case I forget to mention it later, the cross pin has to be shortened a few thousandths when using the Eck keeper.....I'm telling you this now while it just crossed my mind...in case I forget to mention it later..

_________________

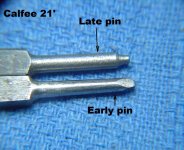

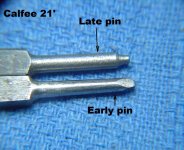

This next picture shows a closeup of the early and late pins........notice there's more meat behind the pin tip of the early pin.....to be able to easily enlarge the footprint....

The late pin is more difficult to enlarge the footprint without moving the entire firing pin forward......

Although, if I had the late pin I'd do whatever it took......this probably really requires the services of a schmidt well versed in rimfire ignition...

_____________________________________

________________________________

This last picture is where it all comes together, which I'll explain later on....

___________________________________

Your pistol fool friend, Bill Calfee

PS:

Bronze and steel are close to the same weight, which is of course much heavier than aluminum..

But man, if one could get carbide weights......one could wake up the Hall spring dependent ignition even more......

______________________

I need a favor of you CYA folks....

If you have comments about any of this, please withhold them until I get through this thing because it's fairly complicated and needs to be condensed as much as possible......OK.

_____________________

PS #2:

I finally located the picture of an early Hall footprint, right, and the footprint after my modification...left.

An amazing difference.....

This picture was taken in November of 2003.....